- Home

- Machinery Directive

- History of the Machinery Directive 2006/42/EC

- Machinery directive 2006/42/EC

- Whereas of machinery directive 2006/42/EC

- Articles of machinery directive 2006/42/EC

- Article 1 of machinery directive 2006/42/EC - Scope

- Article 2 of machinery directive 2006/42/EC - Definitions

- Article 3 : Specific Directives of machinery directive 2006/42/EC

- Article 4 : Market surveillance of machinery directive 2006/42/EC

- Article 5 : Placing on the market and putting into service - machinery directive 2006/42/EC

- Article 6 : Freedom of movement - machinery directive 2006/42/EC

- Article 7 : Presumption of conformity and harmonised standards - machinery directive 2006/42/EC

- Article 8 : Specific measures - machinery directive 2006/42/EC

- Article 9 : Specific measures to deal with potentially hazardous machinery - machinery directive 2006/42/EC

- Article 10 : Procedure for disputing a harmonised standard - machinery directive 2006/42/EC

- Article 11 : Safeguard clause - machinery directive 2006/42/EC

- Article 12 : Procedures for assessing the conformity of machinery - machinery directive 2006/42/EC

- Article 13 : Procedure for partly completed machinery - 2006/42/EC

- Article 14 : Notified bodies - machinery directive 2006/42/EC

- Article 15 : Installation and use of machinery - machinery directive 2006/42/EC

- Article 16 : CE marking - machinery directive 2006/42/EC

- Article 17 : Non-conformity of marking - machinery directive 2006/42/EC

- Article 18 : Confidentiality - machinery directive 2006/42/EC

- Article 19 : Cooperation between Member States - machinery directive 2006/42/EC

- Article 20 : Legal remedies - machinery directive 2006/42/EC

- Article 21 : Dissemination of information - machinery directive 2006/42/EC

- Article 22 : Committee - machinery directive 2006/42/EC

- Article 23 : Penalties - machinery directive 2006/42/EC

- Article 24 : Amendment of Directive 95/16/EC - machinery directive 2006/42/EC

- Article 25 : Repeal - machinery directive 2006/42/EC

- Article 26 : Transposition - machinery directive 2006/42/EC

- Article 27 : Derogation - machinery directive 2006/42/EC

- Article 28 : Entry into force - machinery directive 2006/42/EC

- Article 29 : Addressees - machinery directive 2006/42/EC

- ANNEX I of machinery directive 2006/42/EC - Summary

- GENERAL PRINCIPLES of annex 1 of machinery directive 2006/42/EC

- 1 ESSENTIAL HEALTH AND SAFETY REQUIREMENTS of annex 1 - definitions - machinery directive 2006/42/EC

- Article 1.1.2. Principles of safety integration of annex 1 machinery directive 2006/42/EC

- Article 1.1.3. Materials and products annex 1 machinery directive 2006/42/EC

- Article 1.1.4. Lighting - annex 1 machinery directive 2006/42/EC

- Article 1.1.5. Design of machinery to facilitate its handling - annex 1 machinery directive 2006/42/EC

- Article 1.1.6. Ergonomics - annex 1 machinery directive 2006/42/EC

- Article 1.1.7. Operating positions - annex 1 machinery directive 2006/42/EC

- Article 1.1.8. Seating - annex 1 machinery directive 2006/42/EC

- Article 1.2.1. Safety and reliability of control systems - annex 1 of machinery directive 2006/42/EC

- Article 1.2.2. Control devices - annex 1 of machinery directive 2006/42/EC

- Article 1.2.3. Starting - annex 1 of machinery directive 2006/42/EC

- Article 1.2.4. Stopping - annex 1 of machinery directive 2006/42/EC

- Article 1.2.4.4. Assembly of machinery - Annex 1 of machinery directive 2006/42/EC

- Article 1.2.5. Selection of control or operating modes - annex 1 of machinery directive 2006/42/EC

- Article 1.2.6. Failure of the power supply - annex 1 of machinery directive 2006/42/EC

- Article 1.3. PROTECTION AGAINST MECHANICAL HAZARDS - annex 1 of machinery directive 2006/42/EC

- Article 1.4. REQUIRED CHARACTERISTICS OF GUARDS AND PROTECTIVE DEVICES - annex 1 of machinery directive 2006/42/EC

- Article 1.5. RISKS DUE TO OTHER HAZARDS - annex 1 of machinery directive 2006/42/EC

- Article 1.6. MAINTENANCE - annex 1 of machinery directive 2006/42/EC

- Article 1.7. INFORMATION - annex 1 of machinery directive 2006/42/EC

- Article 2. SUPPLEMENTARY ESSENTIAL HEALTH AND SAFETY REQUIREMENTS - annex 1 machinery directive 2006/42/EC

- Article 3. SUPPLEMENTARY ESSENTIAL HEALTH TO THE MOBILITY OF MACHINERY - annex 1 machinery directive 2006/42/EC

- Article 4. SUPPLEMENTARY REQUIREMENTS TO OFFSET HAZARDS DUE TO LIFTING OPERATIONS of machinery directive 2006/42/EC

- Article 5. SUPPLEMENTARY ESSENTIAL HEALTH AND SAFETY REQUIREMENTS FOR UNDERGROUND WORK of machinery directive 2006/42/EC

- Article 6. SUPPLEMENTARY REQUIREMENTS - HAZARDS DUE TO THE LIFTING OF PERSONS of machinery directive 2006/42/EC

- Annex II : Declarations of CONFORMITY OF THE MACHINERY, DECLARATION OF INCORPORATION - machinery directive 2006/42/EC

- Annex III of machinery directive 2006/42/EC - CE marking

- Annex IV of machinery directive 2006/42/EC

- Annex V of machinery directive 2006/42/EC

- Annex VI of machinery directive 2006/42/EC

- Annex VII - Technical file for machinery - machinery directive 2006/42/EC

- Annex VIII - Assessment of conformity of machinery directive 2006/42/EC

- Annex IX of machinery directive 2006/42/EC - EC type-examination

- Annex X of machinery directive 2006/42/EC - Full quality assurance

- Annex XI of machinery directive 2006/42/EC - Minimum criteria for the notification of bodies

- Annex XII of machinery directive 2006/42/EC - Correlation table between machinery directive 2006/42/CE and MD 1998/37/CE

- Machinery directive 1998/37/EC

- considerings of machinery directive 1998/37/CE

- articles of 1998/37/EC machinery directive

- Annex I of 1998/37/CE machinery directive

- Annex II of 1998/37/EC machinery directive

- Annex III of machinery directive 1998/37/CE

- Annex IV of machine directive 1998/37/EC

- Annex V of machines directive 1998/37/CE

- Annex VI of machines directive 1998/37/EC

- Annex VII of machines directive 1998/37/EC

- Annex VIII of 1998/37/CE machine directive

- Annex IX of machinery directive 1998/37/CE

- Machinery directive 1989/392/EC

- whereas of machinery directive machines 1989/392/EEC

- articles of machinery directive 1989/392/EEC

- Annex I of machinery directive 1989/392/EEC

- Annex II of machine directive 1989/392/EEC

- Annex III of machinery directive 1989/392/EEC

- Annex IV of machinery directive 1989/392/EEC

- Annex V of machinery directive 1989/392/EEC

- Annex VI of machine directive 1989/392/EEC

- Annexe VII of machinery directive 1989/392/EEC

- Amendments of 1989/392/EEC directive

- ATEX directives

- ATEX 94/9/EC directive

- Whereas of ATEX 94/9/CE directive

- Articles of ATEX 94/9/CE directive

- article 1 ATEX 94/9/EC directive

- article 2 ATEX 94/9/EC directive

- article 3 ATEX 94/9/EC directive

- article 4 : ATEX 94/9/EC directive

- article 5 : ATEX 94/9/EC directive

- article 6 : ATEX 94/9/EC directive

- article 7 : ATEX 94/9/EC directive

- article 8 ATEX 94/9/EC directive

- article 9 : ATEX 94/9/EC directive

- article 10 : ATEX 94/9/EC directive

- article 11 : ATEX 94/9/EC directive

- article 12 : ATEX 94/9/EC directive

- article 13 : ATEX 94/9/EC directive

- article 14 : ATEX 94/9/EC directive

- article 15 : ATEX 94/9/EC directive

- article 16 : ATEX 94/9/EC directive

- ANNEX I of ATEX 94/9/EC directive : CRITERIA DETERMINING THE CLASSIFICATION OF EQUIPMENT-GROUPS INTO CATEGORIES

- ANNEX II of ATEX 94/9/EC : directive ESSENTIAL HEALTH AND SAFETY REQUIREMENTS -EHSR

- ANNEX III of ATEX 94/9/EC directive : MODULE EC-TYPE EXAMINATION

- ANNEX IV of ATEX 94/9/EC directive : MODULE PRODUCTION QUALITY ASSURANCE

- ANNEX V of ATEX 94/9/EC directive : MODULE PRODUCT VERIFICATION

- ANNEX VI of ATEX 94/9/EC directive : MODULE CONFORMITY TO TYPE

- ANNEX VII of ATEX 94/9/EC directive : MODULE PRODUCT QUALITY ASSURANCE

- ANNEX VIII of ATEX 94/9/EC directive : MODULE INTERNAL CONTROL OF PRODUCTION

- ANNEX IX of ATEX 94/9/EC directive : MODULE UNIT VERIFICATION

- ANNEX X of ATEX 94/9/EC directive : CE Marking - Content of the EC declaration of conformity

- ANNEX XI of ATEX 94/9/EC directive: NOTIFICATION OF BODIES

- ATEX 99/92/EC Directive

- ATEX DIRECTIVE 2014/34/UE

- whereas of 2014/34/UE ATEX directive

- Articles of ATEX 2014/34/UE directive

- Annex 1 of ATEX 2014/34/UE directive

- Annex 2 of the ATEX 2014/34/UE directive

- Annex 3 of ATEX 2014/34/UE directive

- Annex 4 of ATEX 2014/34/UE directive

- Annex 5 of ATEX 2014/34/UE directive

- Annex 6 of ATEX 2014/34/UE directive

- Annex 7 of ATEX 94/9/EC directive

- Annex 8 of the ATEX 2014/34/UE directive

- Annex 9 of the ATEX 2014/34/UE directive

- Annex 10 of ATEX 2014/34/UE directive

- Annex 11 of ATEX 2014/34/UE directive

- Annex 12 of the ATEX 2014/34/UE directive

- Audits in Ex field - EN 13980, OD 005 and EN ISO/CEI 80079-34

- New ATEX directive

- RASE european project

- ATEX 94/9/EC directive

- IECEX

- Standardization & European Regulation

- Safety of machines : Standardization and European regulations

- European regulation for machines - standardization for machines - harmonized standards

- Standardization in machinery

- EN ISO 12100 - Décembre 2010

- EN ISO 12100-1 - January 2004

- EN ISO 12100-1:2003/A1

- EN ISO 12100-2 November 2003

- EN ISO 12100-2:2003/A1

- EN ISO 14121-1 September 2007

- ISO/TR 14121-2 - 2007

- EN 50205:2002 standard - Relays with forcibly guided (mechanically linked) contacts

- ISO 11161:2007

- ISO 13849-1:2006

- ISO 13849-2:2012

- ISO 13850:2006 - Safety of machinery -- Emergency stop -- Principles for design

- ISO 13851:2002 - Safety of machinery -- Two-hand control devices -- Functional aspects and design principles

- ISO 13854:1996 Safety of machinery - Minimum gaps to avoid crushing of parts of the human body

- ISO 13855:2010 - Safety of machinery -- Positioning of safeguards with respect to the approach speeds of parts of the human body

- ISO 13856-1:2013 Safety of machinery -- Pressure-sensitive protective devices -- Part 1: General principles

- ISO 13856-2:2013 - Safety of machinery -- Pressure-sensitive protective devices -- Part 2: General principles for design testing

- ISO 13856-3:2013 Safety of machinery -- Pressure-sensitive protective devices - Part 3: General principles for design

- ISO 13857:2008 Safety of machinery -- Safety distances to prevent hazard zones

- ISO 14118:2000 - Safety of machinery -- Prevention of unexpected start-up

- ISO 14119:2013- Interlocking devices associated with guards

- ISO 14120:2002 - Guards -- General requirements for the design and construction

- ISO 14122-1:2001 - Permanent means of access to machinery

- ISO 14122-2:2001 - Permanent means of access to machinery

- ISO 14122-4:2004 - Permanent means of access to machinery

- ISO 14123-1:1998 - Reduction of risks to health from hazardous substances emitted by machinery

- ISO 14123-2:1998 - Reduction of risks to health from hazardous substances emitted by machinery

- ISO 14159:2002 - Hygiene requirements for the design of machinery

- ISO 19353:2005 -- Fire prevention and protection

- ISO/AWI 17305 - Safety of machinery - Safety functions of control systems

- ISO/DTR 22100-2 - Safety of machinery -- Part 2: How ISO 12100 relates to ISO 13849-1

- ISO/TR 14121-2:2012 - Risk assessment - Part 2: Practical guidance

- ISO/TR 18569:2004 - Guidelines for the understanding and use of safety of machinery standards

- ISO/TR 23849:2010 - Guidance on the application of ISO 13849-1 and IEC 62061 in the design of safety-related control systems

- STABILITY DATES FOR Machinery STANDARDS

- harmonized standards list - machinery-directive 2006/42/CE

- Publication of harmonised standards for machinery directive 2006/42/EC - 9.3.2018

- Harmonized standard list - machinery directive 2006/42/EC - 9.6.2017

- Harmonized standards for machinery - OJ C 2016/C173/01 of 15/05/2016

- Harmonized standards for machinery -OJ C 2016/C14/102 of 15/01/2016

- Harmonized standards for machinery - corrigendum OJ C 2015/C 087/03 of 13/03/2015

- harmonized standards for machinery - OJ C 2015/C 054/01 of 13/02/2015

- Application guide for machinery directive 2006/42/EC

- Guide to application of the machinery directive 2006/42/CE - July 2017

- Guide to application of the Machinery Directive 2006/42/EC - second edition June 2010

- Guide to application of machinery directive - 1-2 : The citations

- Guide to application of machinery directive - § 3 to § 31 The Recitals

- Guide to application of machinery directive - § 32 to § 156 - The Articles

- Guide to application of machinery directive - § 157 to § 381 - Annex I

- Guide to application of machinery directive - § 382 to § 386 - ANNEX II Declarations

- Guide to application of machinery directive - § 387 - ANNEX III CE marking

- recommendation for use - machinery directive 2006/42/EC

- Notified bodies under the machinery directive 2006/42/CE

- Safety of Ex, ATEX and IECEx equipments : Standardization

- Standardization in Ex Field

- The transposition of the ATEX 94/9/EC Directive to the 2014/34/EU directive

- harmonized standards list - ATEX directive 2014/34/EU

- Harmonized standard list for ATEX 2014/34/UE - 12-10-2018

- Harmonized standard list for ATEX 2014/34/UE - 15.6.2018

- Harmonized standard list for ATEX 2014/34/UE - 12-07-2019

- Harmonized standard list for ATEX 2014/34/UE - 9.6.2017

- Harmonized standards list ATEX 2014/34/UE directive - OJ C 126 - 08/04/2016

- Guide to application of the ATEX Directive 2014/34/EU

- application guide of 2014/34/EU directive - preambule, citations and recitals

- Guide to application of the ATEX 2014/34/UE directive - THE ARTICLES OF THE ATEX DIRECTIVE

- Guide to application of the ATEX 2014/34/UE directive - ANNEX I CLASSIFICATION INTO CATEGORIES

- Guide to application of the ATEX 2014/34/UE directive - ANNEX II ESSENTIAL HEALTH AND SAFETY REQUIREMENTS

- Guide to application of the ATEX 2014/34/UE directive - ANNEX III MODULE B: EU-TYPE EXAMINATION

- Guide to application of the ATEX 2014/34/UE directive - ANNEX IV MODULE D: CONFORMITY TO TYPE

- Guide to application of machinery directive - § 388 - ANNEX IV machinery and mandatory certification

- Guide to application of the ATEX 2014/34/UE directive - ANNEX V MODULE F: CONFORMITY TO TYPE

- Alignment of ten technical harmonisation directives - Decision No 768/2008/EC

- ATEX 94/9/EC directive documents

- ATEX 94/9/EC guidelines

- ATEX 94/9/EC guidelines 4th edition

- 1 INTRODUCTION of ATEX 94/9/EC guidelines 4th edition

- 2 OBJECTIVE OF THE ATEX DIRECTIVE 94/9/EC - ATEX 94/9/EC guidelines 4th edition

- 3 GENERAL CONCEPTS of ATEX 94/9/EC directive ATEX 94/9/EC guidelines 4th edition

- 4 IN WHICH CASES DOES DIRECTIVE 94/9/EC APPLY - ATEX 94/9/EC guidelines 4th edition

- 5 EQUIPMENT NOT IN THE SCOPE OF DIRECTIVE 94/9/EC - ATEX 94/9/EC guidelines 4th edition

- 6 APPLICATION OF DIRECTIVE 94/9/EC ALONGSIDE OTHERS THAT MAY APPLY - ATEX 94/9/EC guidelines 4th edition

- 7 USED, REPAIRED OR MODIFIED PRODUCTS AND SPARE PARTS - ATEX 94/9/EC guidelines 4th edition

- 8 CONFORMITY ASSESSMENT PROCEDURES - ATEX 94/9/EC guidelines 4th edition

- 9 NOTIFIED BODIES - ATEX 94/9/EC guidelines 4th edition

- 10 DOCUMENTS OF CONFORMITY - ATEX 94/9/EC guidelines 4th edition

- 11 MARKING - CE marking -ATEX 94/9/EC guidelines 4th edition

- 12 SAFEGUARD CLAUSE AND PROCEDURE - ATEX 94/9/EC guidelines 4th edition

- 13 EUROPEAN HARMONISED STANDARDS - ATEX 94/9/EC guidelines 4th edition

- 14 USEFUL WEBSITES - ATEX 94/9/EC guidelines 4th edition

- ANNEX I: SPECIFIC MARKING OF EXPLOSION PROTECTION - ATEX 94/9/EC guidelines 4th edition

- ANNEX II: BORDERLINE LIST - ATEX PRODUCTS - ATEX 94/9/EC guidelines 4th edition

- ATEX 94/9/EC guidelines 4th edition

- Harmonized standards list - ATEX 94/9/EC directive

- Harmonized standards list ATEX 94/9/EC directive - OJ C 126 - 08/04/2016

- Harmonized standards list ATEX 94/9/EC - OJ C 335 - 09/10/2015

- Harmonized standards list ATEX 94/9/EC - OJ-C 445-02 - 12/12/2014

- Harmonized standards list ATEX 94/9/EC - OJ-C 076-14/03/2014

- Harmonized standards list ATEX 94/9/EC - OJ-C 319 05/11/2013

- ATEX 94/9/EC guidelines

- European regulation for ATEX 94/9/EC ATEX directive

- Guide to application of ATEX 2014/34/EU directive second edition

- Safety of machines : Standardization and European regulations

- Latest news & Newsletters

- Functional safety

- Terms and definitions for functional safety

- Safety devices in ATEX

- The SAFEC project

- main report of the SAFEC project

- Appendix 1 of the SAFEC project - guidelines for functional safety

- Appendix 2 of the SAFEC project

- ANNEX A - SAFEC project - DERIVATION OF TARGET FAILURE MEASURES

- ANNEX B - SAFEC project - ASSESSMENT OF CURRENT CONTROL SYSTEM STANDARDS

- ANNEX C - safec project - IDENTIFICATION OF “USED SAFETY DEVICES”

- Annex D - SAFEC project - study of ‘ Used Safety Devices’

- Annex E - Determination of a methodology for testing, validation and certification

- EN 50495 standard for safety devices

- The SAFEC project

- Safety components in Machinery

- STSARCES - Standards for Safety Related Complex Electronic Systems

- STSARCES project - final report

- STSARCES - Annex 1 : Software engineering tasks - Case tools

- STSARCES - Annex 2 : tools for Software - fault avoidance

- STSARCES - Annex 3 : Guide to evaluating software quality and safety requirements

- STSARCES - Annex 4 : Guide for the construction of software tests

- STSARCES - Annex 5 : Common mode faults in safety systems

- STSARCES - Annex 6 : Quantitative Analysis of Complex Electronic Systems using Fault Tree Analysis and Markov Modelling

- STSARCES - Annex 7 : Methods for fault detection

- STSARCES - Annex 8 : Safety Validation of Complex Components - Validation by Analysis

- STSARCES - Annex 9 : safety Validation of complex component

- STSARCES - Annex 10 : Safety Validation of Complex Components - Validation Tests

- STSARCES - Annex 11 : Applicability of IEC 61508 - EN 954

- STSARCES - Annex 12 : Task 2 : Machine Validation Exercise

- STSARCES - Annex 13 : Task 3 : Design Process Analysis

- STSARCES - Annex 14 : ASIC development and validation in safety components

- Functional safety in machinery - EN 13849-1 - Safety-related parts of control systems

- STSARCES - Standards for Safety Related Complex Electronic Systems

- History of standards for functional safety in machinery

- Basic safety principles - Well-tried safety principles - well tried components

- Functional safety - detection error codes - CRC and Hamming codes

- Functional safety - error codes detection - parity and chechsum

- Functional safety and safety fieldbus

- ISO 13849-1 and SISTEMA

- Prevention of unexpected start-up and machinery directive

- Self tests for micro-controllers

- Validation by analysis of complex safety systems

- basic safety principles - safety relays for machinery

- Download center

- New machinery regulation

- Revision of machinery directive 2006/42/EC

- security for machines

11 MARKING - CE marking -ATEX 94/9/EC guidelines 4th edition

11 MARKING

11.1 CE Marking

As a general rule New Approach directives including Directive 94/9/EC provide for the affixing of the CE marking as part of the conformity assessment procedures in the perspective of total harmonisation. The conformity assessment procedures to be applied are described in the relevant New Approach directives, based on the conformity assessment procedures as defined by Council Decision 93/465/EEC. Where a product is subject to several directives, which all provide for the affixing of CE marking, the marking indicates that the product is presumed to conform to the provisions of all these directives. During the transitional period of a New Approach directive the manufacturer has the choice to either meet the requirements of this directive or the previous relevant regulations. The option chosen, and hence the extent of the conformity expression enshrined in the CE marking, must be indicated by the manufacturer in the accompanying documents.

Any misleading marking in the sense of the any of these directives is forbidden.

As this guide has been especially drafted to facilitate the application of Directive 94/9/EC, the following explanations refer only to this Directive. If other directives are applicable in parallel, their provisions have to be taken into account in addition to those of Directive 94/9/EC.

CE marking is used by the manufacturer as a declaration that he considers that the product in question has been manufactured in conformity with all applicable provisions and requirements of Directive 94/9/EC and that the product has been the subject of the appropriate conformity assessment procedures.

The CE marking is mandatory and must be affixed before any equipment or protective system is placed on the market or put into service. As stated in Article 8 (3) components are excluded from this provision. Instead of being CE marked, components have to be delivered with a written attestation stating the conformity with the provisions of the Directive, stating their characteristics and indicating how they must be incorporated into equipment or protective systems. This separate statement goes along with the definition of components, which have as structural parts no autonomous function.

In general the CE marking must be affixed during the production control phase by the manufacturer or his authorised representative established within the European Union. In certain cases it is possible to affix the CE marking earlier, e.g. during the production phase of a complex product (e.g. a vehicle). It is then necessary that the manufacturer formally confirms the compliance of this product with the requirements of the Directive in the production control phase. The CE marking must consist of the initials "CE" taking the form described in Annex X to Directive 94/9/EC. In general the CE marking must be affixed to the product or to its data plate. However, although it is not a requirement in Directive 94/9/EC, it is considered reasonable to affix the CE marking to the packaging and to the accompanying documents if it is not possible to affix it to the product because of the product's size or nature.

It would be sensible, but it is not mandatory, to affix the CE marking to more than one place, for example, marking the outer packaging as well as the product inside, would mean that the marking can be ascertained without opening the package.

The CE marking shall be affixed distinctly, visibly, legibly and indelibly. It is prohibited to affix any marks or inscriptions that are likely to mislead third parties as to the meaning and form of the CE marking. The requirement for visibility means that the CE marking must be easily accessible for market surveillance authorities as well as visible for customers and users. For reasons of legibility a minimum height of 5 mm of the CE marking is required. This minimum dimension may be waived for small-scale products. The requirement for indelibility means that the marking must not be removed from the product without leaving traces noticeable under normal circumstances.

Depending on the conformity assessment procedure applied, a Notified Body may be involved in the design phase (Annex III), the production phase (Annexes IV, V, VI, VII, IX) or in both phases. The identification number of the Notified Body only has to accompany the CE marking if the Body is involved in the production control phase (see Article 10(1) of Directive 94/9/EC). It is necessary to avoid any misleading information on equipment, for example the number of the Notified Body, where this is not foreseen by the Directive. Hence, the product should not have the number of a Notified Body affixed, if falling under Category 3 (other than Unit verification), as well as some Category 2 equipment, and for any voluntary certification.

The CE marking and the identification number of the Notified Body do not necessarily have to be affixed within the territory of the EU. These can be affixed in a third country if the product, for example, is manufactured there and the Notified Body either performed tests on the product type or assessed the quality assurance system of the manufacturer in that country. The CE marking and the identification number can also be affixed separately, so long as the CE and body-number remain combined. In case of components only the identification number of the Notified Body has to be affixed.

Where equipment that has already been placed on the market is incorporated into a product (e.g. an assembly according to 3.7.5.1), the integrated equipment must bear the CE marking and, if appropriate, the identification number of the Notified Body.

Whilst it is recognised that sub assemblies may have CE marking affixed in their own right these might not be visible following construction of the final product. This is acceptable as this information can be found elsewhere. However, the final product must have a single label clearly relating to its final assembly prior to it being placed on the market and/or taken into service. In affixing the CE marking to the final product the manufacturer or his authorised representative accepts full responsibility for the conformity of the final product to the applicable Essential Health and Safety Requirements of Directive 94/9/EC and all other relevant directives.

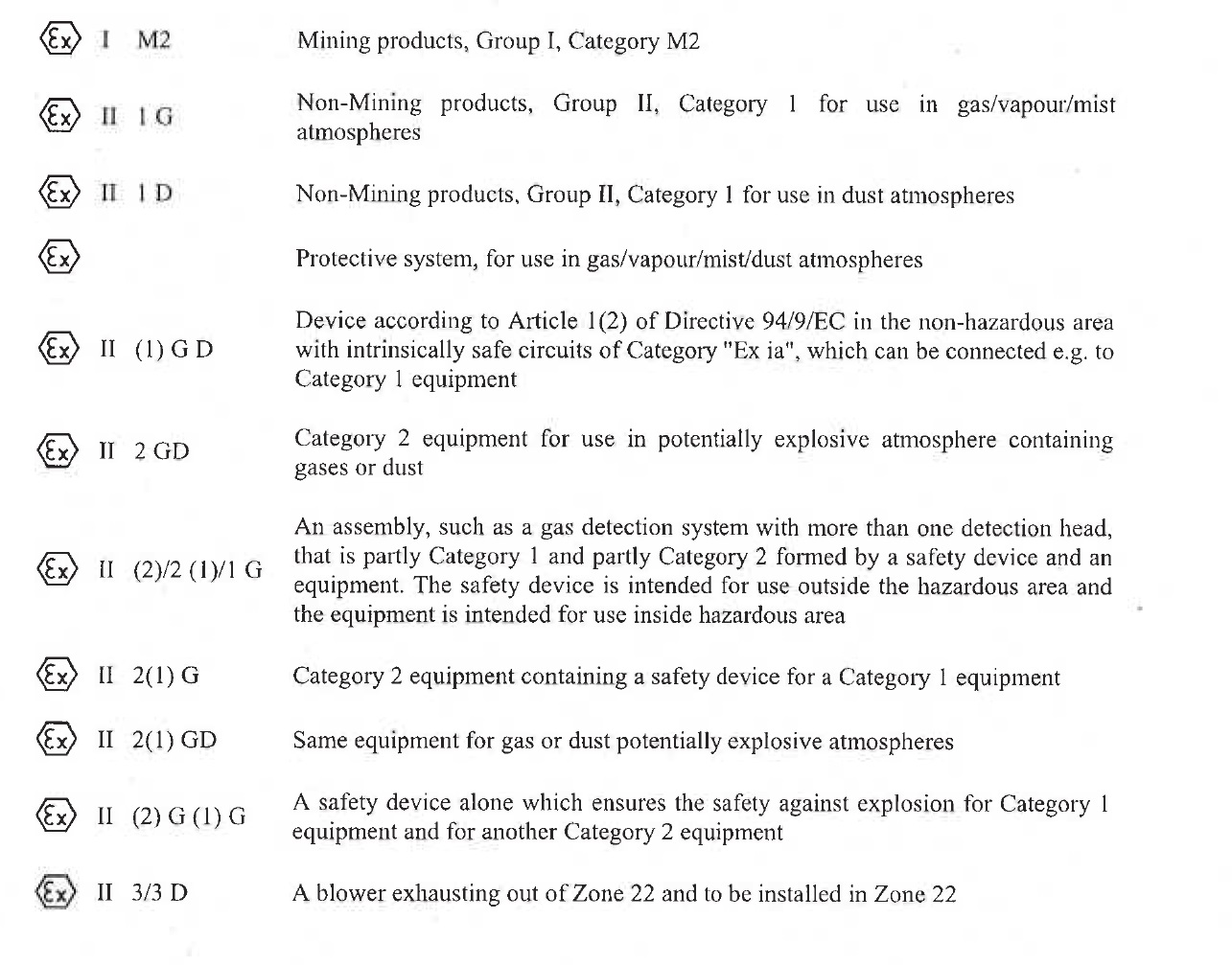

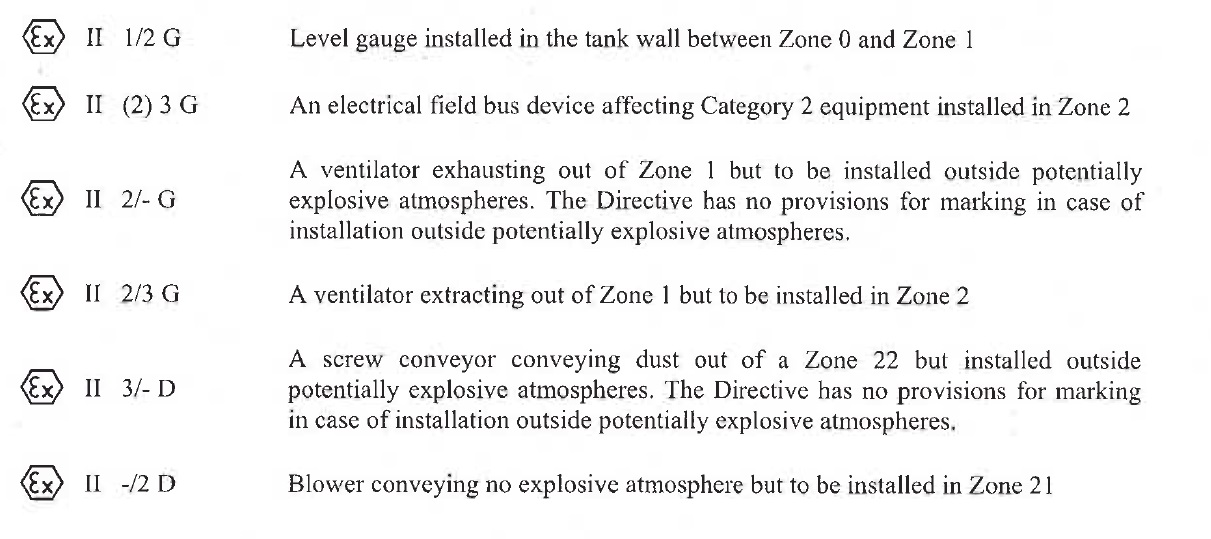

11.2 Supplementary/Specific Marking

It is the intention of Directive 94/9/EC that the design of the specific marking of explosion protection follows the design, as specified in Directive 84/47/EEC. Although there is no requirement in Directive 94/9/EC it is recommended to continue to use the established design (see Annex I to these Guidelines). This marking has to be followed by the symbol of the group and category (on devices according to Article 1(2) of Directive 94/9/EC the category should be indicated in brackets) and, relating to Group II, the letter ‘G’ (concerning explosive atmospheres caused by gases, vapours or mists) and/or D (concerning explosive atmospheres caused by dust). User instructions shall explain in detail the meaning of the marking on the product. However it is recommended to use the format provided in the following examples, where

follows the design, as specified in Directive 84/47/EEC. Although there is no requirement in Directive 94/9/EC it is recommended to continue to use the established design (see Annex I to these Guidelines). This marking has to be followed by the symbol of the group and category (on devices according to Article 1(2) of Directive 94/9/EC the category should be indicated in brackets) and, relating to Group II, the letter ‘G’ (concerning explosive atmospheres caused by gases, vapours or mists) and/or D (concerning explosive atmospheres caused by dust). User instructions shall explain in detail the meaning of the marking on the product. However it is recommended to use the format provided in the following examples, where

" .. / .. " means the product has two different categories

".. - .. " means that a part of the product is not conforming to the Directive and not intended to be used in a potentially explosive atmosphere.

Moreover, devices according to Article 1.2 of the Directive, and separately placed on the market, shall be marked with the category of the equipment under control in round brackets, and such devices which contain an own potential ignition source intended for use in a potential explosive atmosphere shall be marked as equipment according to Annex II clause 1.0.5.

Examples for marking of equipment having different categories are:

All products must be marked with the name and address of the manufacturer, designation of series or type, serial number (if any) and the year of construction. The product must be accompanied with written information explaining the different categories and the consequences for the intended use.

Where a product is covered by more than one New Approach directive, CE marking denotes compliance with the appropriate provisions of all relevant directives. However, where one or more of these directives are in their transitional period and, as a consequence, allow the manufacturer to choose which arrangements to apply, the CE marking indicates conformity only to those directives where application is mandatory and others which are so applied. In the case of these latter directives particulars must be given in the documents, notices or instructions accompanying the product or, where appropriate, on the data plate.

11.3 Additional marking for standards

Because of the special importance for the safety of products intended for use in potentially explosive atmospheres and in order to avoid any misunderstandings Directive 94/9/EC provides for additional markings (see Annex II 1.0.5. Marking).

It is stated in Annex II 1.0.5 to the Directive that equipment, protective systems and components must furthermore be marked with all necessary information essential to the safe use. According to this requirement European standards for electrical and non-electrical products for potentially explosive atmospheres foresee a supplementary marking. For detailed and complete information about this marking it is necessary to use these standards.

11.4 Marking of components

The person responsible for the placing on the market and/or the putting into service of a product has to mark it with the name and the address of the manufacturer, according to Annex II to Directive 94/9/EC, clause 1.0.5. The Directive leaves it free to choose between trademark and company name if there is a difference. The address must be shown on the marking. This address can be simplified if there is not really enough room on small products, as long as the responsible person can always be identified. In any event, the address on the plaque must be sufficient for mail to reach the company. An internet address is not sufficient but the postal address has to be given. In some countries a unique postal code identifies an address. The use of this postal code is sufficient with the country.

The question has arisen, whether the marking of components is mandatory.

Strictly speaking, Directive 94/9/EC explicitly requires marking in Annex II, clause 1.0.5., only for equipment and protective systems. The question, whether components should nevertheless be marked in order to facilitate the implementation to the Directive, has particular practical relevance in cases

- where it is difficult to recognise the difference between ATEX components and standard components, and

- where a manufacturer who wanted to use a component might have serious problems undertaking his risk assessment, if there is no indication about the category of the component.

Apart from the question of marking, the Directive requires an attestation of conformity for components. The latter shall give all the necessary information stating the characteristics. This normally occurs assigning to the component an explosion classification according to relevant harmonised standards, which looks like a marking (e.g. Ex II 1/2 GD cb Tx or Ex II 1 GD c Tx).

For components having an own potential ignition source or which are clearly correlated (with respect to the properties of the component) to equipment with a given category, it has been considered that without the definition of group and category, the necessary conformity procedure of the equipment, which the component will be incorporated to, cannot be performed.

In some cases the conformity procedure can only be performed, if the equipment, which the component will be incorporated to, is defined, and if this incorporation is a matter of the conformity procedure.

Therefore, it is recommended to mark components, as long as these can be assessed with respect to a certain category and group of equipment, indicating this category and group in the marking.

Moreover, it is recommended to mark components for autonomous protective systems, which can be assessed with respect to the characteristic properties of the latter, as far as reasonable indicating these characteristics in the marking.

It has also to be considered that size is a problem impeding marking on a product. In these cases, the information should be given in the accompanying documentation and on the packaging of the component subject to marking.

Finally, it is recalled that, according to Directive 94/9/EC, ATEX components shall not bear the CE-marking.

11.5 Marking of small products

In accordance with the guidance given to the CE marking of products, it is also considered reasonable to affix all other marking to the packaging and the accompanying documents if it is not possible to affix it to the product because of the product's size or nature.

On very small products where a reduction in the marking is unavoidable, the following information is nevertheless required:

- CE marking (not for components),

- Ex marking,

the name or registered trade mark of the manufacturer.

11.6 Marking of assemblies

The marking of assemblies is identical to the marking of equipment, in particular equipment having different categories. An assembly may consist of a large number of assessed and compliant items (equipment, protective systems, safety devices) with their own specific marking, potentially of different categories. In such cases it would not be helpful to show all of these the individual markings in the marking of the complete assembly. Nevertheless, the marking of the assembly has to display all relevant information required by Annex II, 1.0.5, of Directive 94/9/EC necessary for the intended use of the assembly as a whole. The marking shall be placed in such a way – e.g. on the outer housing of the assembly – so that there is no doubt that it shows the characteristics of the whole assembly and not just one part.

Assemblies may consist of parts of different categories and be intended for potentially explosive atmospheres having different physical characteristics. The marking of the assembly as a whole with group, categories and additional information essential for the safe use of the assembly (temperature class, etc.) may fall under one of the two following scenarios:

Case 1: The assembly as a whole is intended for use in one potentially explosive atmosphere of one specific zone

Where the individual parts of the assembly are marked for potentially explosive atmospheres having different characteristics, the part with the lowest level of safety defines the marking of the whole assembly. That means that the category, temperature class, explosion group etc with the lowest requirement for the equipment has to be used for the marking of the whole assembly.

Case 2: Parts of the assembly are intended for use in potentially explosive atmospheres having different physical characteristics and/or different zones

If it is essential for that intended use, the marking of the assembly shall contain all groups, categories and additional markings (temperature class, etc.) necessary for the intended atmospheres. In this case, the instructions for use, installation etc. will indicate the different atmospheres/zones intended (and/or provided by constructional measures) in or around different parts of the equipment.

Examples (only categories and additional markings essential for safe use are given in these examples):

Examples for case 1:

- An assembly consisting of parts marked with T3 and other parts with T6 shall be marked T3 to indicate, that it is, as a whole, intended for use in T3 atmospheres.

- A pump unit consisting of a liquid pump (non flammable liquid) and driving electric motor. The pump is marked II 2 G T6, the motor II 2 G IIB T4. The whole assembly shall be marked II 2 G IIB T4, as the motor is the part that meets the lower requirements.

- • A similar pump unit with a pump conveying hot liquid (non flammable). The pump is marked II 2 G T3, the motor II 2G IIB T4. In this case the assembly shall be marked II 2 G IIB T3. Examples for case 2:

- A fan conveying a IIA T3 explosive atmosphere (Zone 1), the fan fitted with an electric motor and some control devices placed in a Zone 2, the fan accordingly marked II 2/3 G IIA T3. The motor is marked II 3 G T3, the intrinsic safe control device II 2 G IIC T6. As the intrinsic safe control device is placed in the same atmosphere as the motor, the part meeting the lower requirements (in this case the motor) is the decisive item. Accordingly the marking of the whole assembly is II 2/3 G IIA T3.

- A similar fan assembly, but with the motor placed outside the hazardous area. The marking of the whole assembly is II 2/3/- G IIA T3.

English