- Home

- Machinery Directive

- History of the Machinery Directive 2006/42/EC

- Machinery directive 2006/42/EC

- Whereas of machinery directive 2006/42/EC

- Articles of machinery directive 2006/42/EC

- Article 1 of machinery directive 2006/42/EC - Scope

- Article 2 of machinery directive 2006/42/EC - Definitions

- Article 3 : Specific Directives of machinery directive 2006/42/EC

- Article 4 : Market surveillance of machinery directive 2006/42/EC

- Article 5 : Placing on the market and putting into service - machinery directive 2006/42/EC

- Article 6 : Freedom of movement - machinery directive 2006/42/EC

- Article 7 : Presumption of conformity and harmonised standards - machinery directive 2006/42/EC

- Article 8 : Specific measures - machinery directive 2006/42/EC

- Article 9 : Specific measures to deal with potentially hazardous machinery - machinery directive 2006/42/EC

- Article 10 : Procedure for disputing a harmonised standard - machinery directive 2006/42/EC

- Article 11 : Safeguard clause - machinery directive 2006/42/EC

- Article 12 : Procedures for assessing the conformity of machinery - machinery directive 2006/42/EC

- Article 13 : Procedure for partly completed machinery - 2006/42/EC

- Article 14 : Notified bodies - machinery directive 2006/42/EC

- Article 15 : Installation and use of machinery - machinery directive 2006/42/EC

- Article 16 : CE marking - machinery directive 2006/42/EC

- Article 17 : Non-conformity of marking - machinery directive 2006/42/EC

- Article 18 : Confidentiality - machinery directive 2006/42/EC

- Article 19 : Cooperation between Member States - machinery directive 2006/42/EC

- Article 20 : Legal remedies - machinery directive 2006/42/EC

- Article 21 : Dissemination of information - machinery directive 2006/42/EC

- Article 22 : Committee - machinery directive 2006/42/EC

- Article 23 : Penalties - machinery directive 2006/42/EC

- Article 24 : Amendment of Directive 95/16/EC - machinery directive 2006/42/EC

- Article 25 : Repeal - machinery directive 2006/42/EC

- Article 26 : Transposition - machinery directive 2006/42/EC

- Article 27 : Derogation - machinery directive 2006/42/EC

- Article 28 : Entry into force - machinery directive 2006/42/EC

- Article 29 : Addressees - machinery directive 2006/42/EC

- ANNEX I of machinery directive 2006/42/EC - Summary

- GENERAL PRINCIPLES of annex 1 of machinery directive 2006/42/EC

- 1 ESSENTIAL HEALTH AND SAFETY REQUIREMENTS of annex 1 - definitions - machinery directive 2006/42/EC

- Article 1.1.2. Principles of safety integration of annex 1 machinery directive 2006/42/EC

- Article 1.1.3. Materials and products annex 1 machinery directive 2006/42/EC

- Article 1.1.4. Lighting - annex 1 machinery directive 2006/42/EC

- Article 1.1.5. Design of machinery to facilitate its handling - annex 1 machinery directive 2006/42/EC

- Article 1.1.6. Ergonomics - annex 1 machinery directive 2006/42/EC

- Article 1.1.7. Operating positions - annex 1 machinery directive 2006/42/EC

- Article 1.1.8. Seating - annex 1 machinery directive 2006/42/EC

- Article 1.2.1. Safety and reliability of control systems - annex 1 of machinery directive 2006/42/EC

- Article 1.2.2. Control devices - annex 1 of machinery directive 2006/42/EC

- Article 1.2.3. Starting - annex 1 of machinery directive 2006/42/EC

- Article 1.2.4. Stopping - annex 1 of machinery directive 2006/42/EC

- Article 1.2.4.4. Assembly of machinery - Annex 1 of machinery directive 2006/42/EC

- Article 1.2.5. Selection of control or operating modes - annex 1 of machinery directive 2006/42/EC

- Article 1.2.6. Failure of the power supply - annex 1 of machinery directive 2006/42/EC

- Article 1.3. PROTECTION AGAINST MECHANICAL HAZARDS - annex 1 of machinery directive 2006/42/EC

- Article 1.4. REQUIRED CHARACTERISTICS OF GUARDS AND PROTECTIVE DEVICES - annex 1 of machinery directive 2006/42/EC

- Article 1.5. RISKS DUE TO OTHER HAZARDS - annex 1 of machinery directive 2006/42/EC

- Article 1.6. MAINTENANCE - annex 1 of machinery directive 2006/42/EC

- Article 1.7. INFORMATION - annex 1 of machinery directive 2006/42/EC

- Article 2. SUPPLEMENTARY ESSENTIAL HEALTH AND SAFETY REQUIREMENTS - annex 1 machinery directive 2006/42/EC

- Article 3. SUPPLEMENTARY ESSENTIAL HEALTH TO THE MOBILITY OF MACHINERY - annex 1 machinery directive 2006/42/EC

- Article 4. SUPPLEMENTARY REQUIREMENTS TO OFFSET HAZARDS DUE TO LIFTING OPERATIONS of machinery directive 2006/42/EC

- Article 5. SUPPLEMENTARY ESSENTIAL HEALTH AND SAFETY REQUIREMENTS FOR UNDERGROUND WORK of machinery directive 2006/42/EC

- Article 6. SUPPLEMENTARY REQUIREMENTS - HAZARDS DUE TO THE LIFTING OF PERSONS of machinery directive 2006/42/EC

- Annex II : Declarations of CONFORMITY OF THE MACHINERY, DECLARATION OF INCORPORATION - machinery directive 2006/42/EC

- Annex III of machinery directive 2006/42/EC - CE marking

- Annex IV of machinery directive 2006/42/EC

- Annex V of machinery directive 2006/42/EC

- Annex VI of machinery directive 2006/42/EC

- Annex VII - Technical file for machinery - machinery directive 2006/42/EC

- Annex VIII - Assessment of conformity of machinery directive 2006/42/EC

- Annex IX of machinery directive 2006/42/EC - EC type-examination

- Annex X of machinery directive 2006/42/EC - Full quality assurance

- Annex XI of machinery directive 2006/42/EC - Minimum criteria for the notification of bodies

- Annex XII of machinery directive 2006/42/EC - Correlation table between machinery directive 2006/42/CE and MD 1998/37/CE

- Machinery directive 1998/37/EC

- considerings of machinery directive 1998/37/CE

- articles of 1998/37/EC machinery directive

- Annex I of 1998/37/CE machinery directive

- Annex II of 1998/37/EC machinery directive

- Annex III of machinery directive 1998/37/CE

- Annex IV of machine directive 1998/37/EC

- Annex V of machines directive 1998/37/CE

- Annex VI of machines directive 1998/37/EC

- Annex VII of machines directive 1998/37/EC

- Annex VIII of 1998/37/CE machine directive

- Annex IX of machinery directive 1998/37/CE

- Machinery directive 1989/392/EC

- whereas of machinery directive machines 1989/392/EEC

- articles of machinery directive 1989/392/EEC

- Annex I of machinery directive 1989/392/EEC

- Annex II of machine directive 1989/392/EEC

- Annex III of machinery directive 1989/392/EEC

- Annex IV of machinery directive 1989/392/EEC

- Annex V of machinery directive 1989/392/EEC

- Annex VI of machine directive 1989/392/EEC

- Annexe VII of machinery directive 1989/392/EEC

- Amendments of 1989/392/EEC directive

- ATEX directives

- ATEX 94/9/EC directive

- Whereas of ATEX 94/9/CE directive

- Articles of ATEX 94/9/CE directive

- article 1 ATEX 94/9/EC directive

- article 2 ATEX 94/9/EC directive

- article 3 ATEX 94/9/EC directive

- article 4 : ATEX 94/9/EC directive

- article 5 : ATEX 94/9/EC directive

- article 6 : ATEX 94/9/EC directive

- article 7 : ATEX 94/9/EC directive

- article 8 ATEX 94/9/EC directive

- article 9 : ATEX 94/9/EC directive

- article 10 : ATEX 94/9/EC directive

- article 11 : ATEX 94/9/EC directive

- article 12 : ATEX 94/9/EC directive

- article 13 : ATEX 94/9/EC directive

- article 14 : ATEX 94/9/EC directive

- article 15 : ATEX 94/9/EC directive

- article 16 : ATEX 94/9/EC directive

- ANNEX I of ATEX 94/9/EC directive : CRITERIA DETERMINING THE CLASSIFICATION OF EQUIPMENT-GROUPS INTO CATEGORIES

- ANNEX II of ATEX 94/9/EC : directive ESSENTIAL HEALTH AND SAFETY REQUIREMENTS -EHSR

- ANNEX III of ATEX 94/9/EC directive : MODULE EC-TYPE EXAMINATION

- ANNEX IV of ATEX 94/9/EC directive : MODULE PRODUCTION QUALITY ASSURANCE

- ANNEX V of ATEX 94/9/EC directive : MODULE PRODUCT VERIFICATION

- ANNEX VI of ATEX 94/9/EC directive : MODULE CONFORMITY TO TYPE

- ANNEX VII of ATEX 94/9/EC directive : MODULE PRODUCT QUALITY ASSURANCE

- ANNEX VIII of ATEX 94/9/EC directive : MODULE INTERNAL CONTROL OF PRODUCTION

- ANNEX IX of ATEX 94/9/EC directive : MODULE UNIT VERIFICATION

- ANNEX X of ATEX 94/9/EC directive : CE Marking - Content of the EC declaration of conformity

- ANNEX XI of ATEX 94/9/EC directive: NOTIFICATION OF BODIES

- ATEX 99/92/EC Directive

- ATEX DIRECTIVE 2014/34/UE

- whereas of 2014/34/UE ATEX directive

- Articles of ATEX 2014/34/UE directive

- Annex 1 of ATEX 2014/34/UE directive

- Annex 2 of the ATEX 2014/34/UE directive

- Annex 3 of ATEX 2014/34/UE directive

- Annex 4 of ATEX 2014/34/UE directive

- Annex 5 of ATEX 2014/34/UE directive

- Annex 6 of ATEX 2014/34/UE directive

- Annex 7 of ATEX 94/9/EC directive

- Annex 8 of the ATEX 2014/34/UE directive

- Annex 9 of the ATEX 2014/34/UE directive

- Annex 10 of ATEX 2014/34/UE directive

- Annex 11 of ATEX 2014/34/UE directive

- Annex 12 of the ATEX 2014/34/UE directive

- Audits in Ex field - EN 13980, OD 005 and EN ISO/CEI 80079-34

- New ATEX directive

- RASE european project

- ATEX 94/9/EC directive

- IECEX

- Standardization & European Regulation

- Safety of machines : Standardization and European regulations

- European regulation for machines - standardization for machines - harmonized standards

- Standardization in machinery

- EN ISO 12100 - Décembre 2010

- EN ISO 12100-1 - January 2004

- EN ISO 12100-1:2003/A1

- EN ISO 12100-2 November 2003

- EN ISO 12100-2:2003/A1

- EN ISO 14121-1 September 2007

- ISO/TR 14121-2 - 2007

- EN 50205:2002 standard - Relays with forcibly guided (mechanically linked) contacts

- ISO 11161:2007

- ISO 13849-1:2006

- ISO 13849-2:2012

- ISO 13850:2006 - Safety of machinery -- Emergency stop -- Principles for design

- ISO 13851:2002 - Safety of machinery -- Two-hand control devices -- Functional aspects and design principles

- ISO 13854:1996 Safety of machinery - Minimum gaps to avoid crushing of parts of the human body

- ISO 13855:2010 - Safety of machinery -- Positioning of safeguards with respect to the approach speeds of parts of the human body

- ISO 13856-1:2013 Safety of machinery -- Pressure-sensitive protective devices -- Part 1: General principles

- ISO 13856-2:2013 - Safety of machinery -- Pressure-sensitive protective devices -- Part 2: General principles for design testing

- ISO 13856-3:2013 Safety of machinery -- Pressure-sensitive protective devices - Part 3: General principles for design

- ISO 13857:2008 Safety of machinery -- Safety distances to prevent hazard zones

- ISO 14118:2000 - Safety of machinery -- Prevention of unexpected start-up

- ISO 14119:2013- Interlocking devices associated with guards

- ISO 14120:2002 - Guards -- General requirements for the design and construction

- ISO 14122-1:2001 - Permanent means of access to machinery

- ISO 14122-2:2001 - Permanent means of access to machinery

- ISO 14122-4:2004 - Permanent means of access to machinery

- ISO 14123-1:1998 - Reduction of risks to health from hazardous substances emitted by machinery

- ISO 14123-2:1998 - Reduction of risks to health from hazardous substances emitted by machinery

- ISO 14159:2002 - Hygiene requirements for the design of machinery

- ISO 19353:2005 -- Fire prevention and protection

- ISO/AWI 17305 - Safety of machinery - Safety functions of control systems

- ISO/DTR 22100-2 - Safety of machinery -- Part 2: How ISO 12100 relates to ISO 13849-1

- ISO/TR 14121-2:2012 - Risk assessment - Part 2: Practical guidance

- ISO/TR 18569:2004 - Guidelines for the understanding and use of safety of machinery standards

- ISO/TR 23849:2010 - Guidance on the application of ISO 13849-1 and IEC 62061 in the design of safety-related control systems

- STABILITY DATES FOR Machinery STANDARDS

- harmonized standards list - machinery-directive 2006/42/CE

- Publication of harmonised standards for machinery directive 2006/42/EC - 9.3.2018

- Harmonized standard list - machinery directive 2006/42/EC - 9.6.2017

- Harmonized standards for machinery - OJ C 2016/C173/01 of 15/05/2016

- Harmonized standards for machinery -OJ C 2016/C14/102 of 15/01/2016

- Harmonized standards for machinery - corrigendum OJ C 2015/C 087/03 of 13/03/2015

- harmonized standards for machinery - OJ C 2015/C 054/01 of 13/02/2015

- Application guide for machinery directive 2006/42/EC

- Guide to application of the machinery directive 2006/42/CE - July 2017

- Guide to application of the Machinery Directive 2006/42/EC - second edition June 2010

- Guide to application of machinery directive - 1-2 : The citations

- Guide to application of machinery directive - § 3 to § 31 The Recitals

- Guide to application of machinery directive - § 32 to § 156 - The Articles

- Guide to application of machinery directive - § 157 to § 381 - Annex I

- Guide to application of machinery directive - § 382 to § 386 - ANNEX II Declarations

- Guide to application of machinery directive - § 387 - ANNEX III CE marking

- recommendation for use - machinery directive 2006/42/EC

- Notified bodies under the machinery directive 2006/42/CE

- Safety of Ex, ATEX and IECEx equipments : Standardization

- Standardization in Ex Field

- The transposition of the ATEX 94/9/EC Directive to the 2014/34/EU directive

- harmonized standards list - ATEX directive 2014/34/EU

- Harmonized standard list for ATEX 2014/34/UE - 12-10-2018

- Harmonized standard list for ATEX 2014/34/UE - 15.6.2018

- Harmonized standard list for ATEX 2014/34/UE - 12-07-2019

- Harmonized standard list for ATEX 2014/34/UE - 9.6.2017

- Harmonized standards list ATEX 2014/34/UE directive - OJ C 126 - 08/04/2016

- Guide to application of the ATEX Directive 2014/34/EU

- application guide of 2014/34/EU directive - preambule, citations and recitals

- Guide to application of the ATEX 2014/34/UE directive - THE ARTICLES OF THE ATEX DIRECTIVE

- Guide to application of the ATEX 2014/34/UE directive - ANNEX I CLASSIFICATION INTO CATEGORIES

- Guide to application of the ATEX 2014/34/UE directive - ANNEX II ESSENTIAL HEALTH AND SAFETY REQUIREMENTS

- Guide to application of the ATEX 2014/34/UE directive - ANNEX III MODULE B: EU-TYPE EXAMINATION

- Guide to application of the ATEX 2014/34/UE directive - ANNEX IV MODULE D: CONFORMITY TO TYPE

- Guide to application of machinery directive - § 388 - ANNEX IV machinery and mandatory certification

- Guide to application of the ATEX 2014/34/UE directive - ANNEX V MODULE F: CONFORMITY TO TYPE

- Alignment of ten technical harmonisation directives - Decision No 768/2008/EC

- ATEX 94/9/EC directive documents

- ATEX 94/9/EC guidelines

- ATEX 94/9/EC guidelines 4th edition

- 1 INTRODUCTION of ATEX 94/9/EC guidelines 4th edition

- 2 OBJECTIVE OF THE ATEX DIRECTIVE 94/9/EC - ATEX 94/9/EC guidelines 4th edition

- 3 GENERAL CONCEPTS of ATEX 94/9/EC directive ATEX 94/9/EC guidelines 4th edition

- 4 IN WHICH CASES DOES DIRECTIVE 94/9/EC APPLY - ATEX 94/9/EC guidelines 4th edition

- 5 EQUIPMENT NOT IN THE SCOPE OF DIRECTIVE 94/9/EC - ATEX 94/9/EC guidelines 4th edition

- 6 APPLICATION OF DIRECTIVE 94/9/EC ALONGSIDE OTHERS THAT MAY APPLY - ATEX 94/9/EC guidelines 4th edition

- 7 USED, REPAIRED OR MODIFIED PRODUCTS AND SPARE PARTS - ATEX 94/9/EC guidelines 4th edition

- 8 CONFORMITY ASSESSMENT PROCEDURES - ATEX 94/9/EC guidelines 4th edition

- 9 NOTIFIED BODIES - ATEX 94/9/EC guidelines 4th edition

- 10 DOCUMENTS OF CONFORMITY - ATEX 94/9/EC guidelines 4th edition

- 11 MARKING - CE marking -ATEX 94/9/EC guidelines 4th edition

- 12 SAFEGUARD CLAUSE AND PROCEDURE - ATEX 94/9/EC guidelines 4th edition

- 13 EUROPEAN HARMONISED STANDARDS - ATEX 94/9/EC guidelines 4th edition

- 14 USEFUL WEBSITES - ATEX 94/9/EC guidelines 4th edition

- ANNEX I: SPECIFIC MARKING OF EXPLOSION PROTECTION - ATEX 94/9/EC guidelines 4th edition

- ANNEX II: BORDERLINE LIST - ATEX PRODUCTS - ATEX 94/9/EC guidelines 4th edition

- ATEX 94/9/EC guidelines 4th edition

- Harmonized standards list - ATEX 94/9/EC directive

- Harmonized standards list ATEX 94/9/EC directive - OJ C 126 - 08/04/2016

- Harmonized standards list ATEX 94/9/EC - OJ C 335 - 09/10/2015

- Harmonized standards list ATEX 94/9/EC - OJ-C 445-02 - 12/12/2014

- Harmonized standards list ATEX 94/9/EC - OJ-C 076-14/03/2014

- Harmonized standards list ATEX 94/9/EC - OJ-C 319 05/11/2013

- ATEX 94/9/EC guidelines

- European regulation for ATEX 94/9/EC ATEX directive

- Guide to application of ATEX 2014/34/EU directive second edition

- Safety of machines : Standardization and European regulations

- Latest news & Newsletters

- Functional safety

- Terms and definitions for functional safety

- Safety devices in ATEX

- The SAFEC project

- main report of the SAFEC project

- Appendix 1 of the SAFEC project - guidelines for functional safety

- Appendix 2 of the SAFEC project

- ANNEX A - SAFEC project - DERIVATION OF TARGET FAILURE MEASURES

- ANNEX B - SAFEC project - ASSESSMENT OF CURRENT CONTROL SYSTEM STANDARDS

- ANNEX C - safec project - IDENTIFICATION OF “USED SAFETY DEVICES”

- Annex D - SAFEC project - study of ‘ Used Safety Devices’

- Annex E - Determination of a methodology for testing, validation and certification

- EN 50495 standard for safety devices

- The SAFEC project

- Safety components in Machinery

- STSARCES - Standards for Safety Related Complex Electronic Systems

- STSARCES project - final report

- STSARCES - Annex 1 : Software engineering tasks - Case tools

- STSARCES - Annex 2 : tools for Software - fault avoidance

- STSARCES - Annex 3 : Guide to evaluating software quality and safety requirements

- STSARCES - Annex 4 : Guide for the construction of software tests

- STSARCES - Annex 5 : Common mode faults in safety systems

- STSARCES - Annex 6 : Quantitative Analysis of Complex Electronic Systems using Fault Tree Analysis and Markov Modelling

- STSARCES - Annex 7 : Methods for fault detection

- STSARCES - Annex 8 : Safety Validation of Complex Components - Validation by Analysis

- STSARCES - Annex 9 : safety Validation of complex component

- STSARCES - Annex 10 : Safety Validation of Complex Components - Validation Tests

- STSARCES - Annex 11 : Applicability of IEC 61508 - EN 954

- STSARCES - Annex 12 : Task 2 : Machine Validation Exercise

- STSARCES - Annex 13 : Task 3 : Design Process Analysis

- STSARCES - Annex 14 : ASIC development and validation in safety components

- Functional safety in machinery - EN 13849-1 - Safety-related parts of control systems

- STSARCES - Standards for Safety Related Complex Electronic Systems

- History of standards for functional safety in machinery

- Basic safety principles - Well-tried safety principles - well tried components

- Functional safety - detection error codes - CRC and Hamming codes

- Functional safety - error codes detection - parity and chechsum

- Functional safety and safety fieldbus

- ISO 13849-1 and SISTEMA

- Prevention of unexpected start-up and machinery directive

- Self tests for micro-controllers

- Validation by analysis of complex safety systems

- basic safety principles - safety relays for machinery

- Download center

- New machinery regulation

- Revision of machinery directive 2006/42/EC

- security for machines

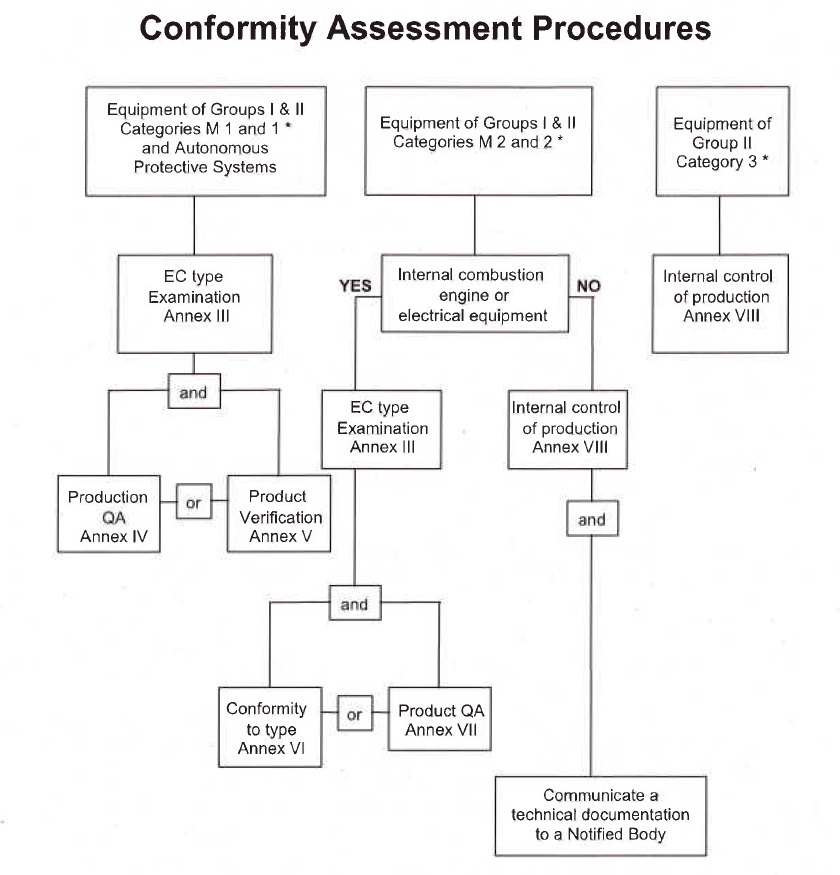

8 CONFORMITY ASSESSMENT PROCEDURES - ATEX 94/9/EC guidelines 4th edition

8 CONFORMITY ASSESSMENT PROCEDURES

8.1 Products conforming to Directive 94/9/EC

Article 8 of the Directive describes the procedures whereby the manufacturer or his authorised representative established within the EU ensures and declares that the product complies with Directive 94/9/EC. For assemblies further guidance is given in chapter 3.7.5.

Article 8.1(a) describes the procedures in the case of equipment; autonomous protective systems; for safety devices for such equipment or systems; and for components for such equipment, systems or devices, under Groups I and II, Categories M1 and 1. The options are either:

i) EC-Type examination42 (Module B)43 followed by:

production quality assurance44 (Module D) or,

product verification45 (Module F);

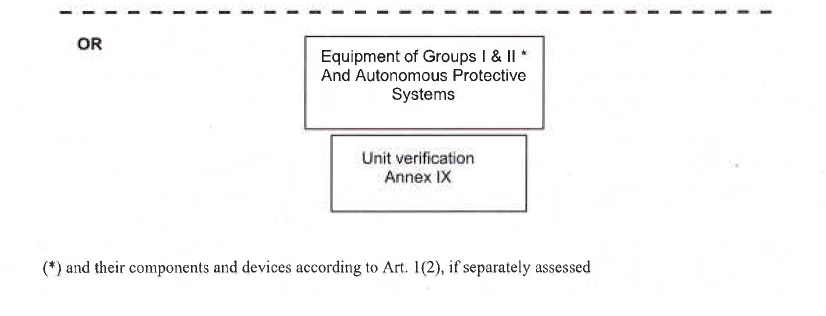

ii) Unit verification46(Module G).

Article 8.1(b) describes the procedure in the case of equipment, for safety devices as described in article 1(2) for such equipment and for components of such equipment or devices, under Groups I and II, Categories M2 and 2. The options are either:

For electrical equipment and internal combustion engines of Categories M2 and 2:

i) EC-Type examination (Module B) followed by:

conformity to type47 (Module C) or,

product quality assurance48 (Module E)

ii) Unit verification (Module G).

For other equipment of Categories M2 and 2:

i) Internal control of production (Module A) and deposit the technical documentation49 with a Notified Body50, or,

ii) Unit verification (Module G).

Article 8.1(c) describes the procedure in the case of equipment; for safety devices for such equipment; and for components for such equipment and devices under Group II, Category 3. The options are either:

i) Internal control of production (Module A) or,

ii) Unit verification (Module G).

42 See Annex III to the Directive. 43 See Council Decision 93/465/EEC of 22 July 1993 concerning the modules for the various phases of the conformity assessment procedures and the rules for the affixing and use of the CE conformity marking,

which are intended to be used in the technical harmonisation directives (OJ L 220, 30.8.1993, p. 23). 44 See Annex IV to the Directive. 45 See Annex V to the Directive. 46 See Annex IX to the Directive. 47 See Annex VI to the Directive. 48 See Annex VII to the Directive. 49 See paragraph 3 of the Annex relating to the internal control of production. 50 Conditions of storage of documents shall be agreed between the Notified Body and its client.

For safety, controlling and regulating devices:

Safety, controlling and regulating devices have to comply with the requirements of Annex II, clause 1, especially clause 1.5.

The formal conformity assessment procedures of Article 8 apply and the safety devices are assessed according to the equipment group and category of the system consisting of the safety device and the equipment under control. In some cases it is necessary to perform the assessment for the combination (e.g. inverter fed motors), but generally the assessment for a group of equipment and the appropriate safety devices can be done separately (e.g. type "e" motor).

Example: A type "e" motor of Category 2 is controlled by an overload protection device located outside the explosive atmosphere. The conformity assessment procedure of equipment group II and Category 2 is applied for the safety device.

In brief, the different conformity assessment procedures are:

EC Type Examination (Annex III): Provides a specimen of the envisaged production to a Notified Body which undertakes the necessary evaluation to determine that the "type" meets the essential requirements of Directive 94/9/EC and issues an EC Type Examination Certificate.

Production Quality Assurance (Annex IV): Operates a quality system approved by a Notified Body for production, final equipment inspection and testing and is subject to on-going surveillance.

Product verification (Annex V): Examination and tests by a Notified Body of every product to check the conformity of the equipment, protective system or device with the requirements of Directive 94/9/EC and draw up a certificate of conformity.

Conformity to type (Annex VI): Tests carried out by a manufacturer on each piece of equipment manufactured to check the explosion protection aspects of the design. Carried out under the responsibility of a Notified Body.

Product Quality Assurance (Annex VII): A quality system approved by a Notified Body for the final inspection and testing of equipment subject to on-going surveillance.

Internal Control of Production (Annex VIII): Product and quality system assessment procedure carried out by the manufacturer and retention of documentation.

Unit verification (Annex IX): Notified Body examines individual equipment or protective system and carry out tests as defined in the harmonised standards, if they exist, or otherwise in European, international or national standards or conduct equivalent tests to ensure conformity with the relevant requirements of Directive 94/9/EC and draw up a certificate of conformity.

Internal Control of Production + Retention of documentation by a Notified Body (Article 8.1((b)(ii):

Product and quality system assessment procedure carried out by the manufacturer and retention of documentation by a Notified Body.

A chart showing the appropriate procedure is provided overleaf:

Conformity Assessment Procedures

Equipment of Groups I & II Categories M 1 and 1 * and Autonomous Protective Systems

|

|

(*) and their components and devices according to Art. 1(2), if separately assessed

Note: According to Article 8.4 for all equipment and protective systems of all groups and categories conformity to 1.2.7 of Annex II of the Directive (protection against other hazards) can be fulfilled by following the procedure of internal control of production (Annex VIII).

Which conformity assessment procedures have to be performed in the case of different categories within one product, or mixes of equipment and protective systems according to Article 1.3 b ?

If a product is made of parts which are assigned to different conformity assessment procedures it will be up to the manufacturer to decide how these parts and the whole product shall be placed on the market. The manufacturer can decide to realise the appropriate conformity assessment procedures for each part or for the whole product, even if he decides to place the product as an entity on the market. In the case of separate conformity assessment procedures for each part of the assembled equipment (called assembly in the Guidelines to Directive 94/9/EC), the manufacturer may presume conformity of these pieces of equipment and may restrict his own risk assessment of the assembly to those additional ignition and other hazards, which become relevant because of the final combination. If additional hazards are identified a further conformity assessment of the assembly regarding these additional risks is necessary.

If the manufacturer explicitly asks a Notified Body to assess the entire product, then that conformity assessment procedure has to be applied, which covers the highest requirements. The Notified Body shall include into the EC-Type examination (if relevant) all aspects of the product. Existing conformity declarations of the manufacturer for parts of the product should be given due consideration.

The Notified Body should inform the manufacturer about the possibilities of separate conformity assessment procedures for each part of the assembly as pointed out by the Guidelines to Directive 94/9/EC.

Any certificate issued by the Notified Body should make clear which aspects of the product have been assessed by the NB, and which have been assessed by the manufacturer alone.

Example: Vapour recovery pump for petrol stations

(a) The pump is sucking the petrol vapour-air mixture from the atmosphere and conveying it in pipework attributed to Zone 0. Accordingly it is connected at its inlet and outlet to a potentially explosive atmosphere classified as Zone 0. The pump itself is placed in a Zone 1 environment.

With regard to the inlet and outlet connection the pump then has to comply with the requirements for Category 1 equipment. The corresponding EC-Type examination (equipment) has to be carried out by a Notified Body. With regard to the remaining (outer) body and integrated parts of the pump the Notified Body includes the necessary Category 2 assessment into the certification, even if there are only non-electrical ignition sources to be considered.

Both categories shall be indicated in the EC-Type Examination Certificate, making clear which aspects of the product have been assessed by the Notified Body, and which have been assessed by the manufacturer alone, and in the marking. For those Category 2 parts of the pump, which show only non-electrical ignition sources and which are placed separately on the market, and for which the technical documentation has been communicated to a Notified Body, an EC declaration of conformity (for equipment) or a written attestation of conformity (for components) of the manufacturer are sufficient.

(b) Often the pump is expected to prevent the passage of a deflagration flame from the inlet to the outlet connection, as typical vapour recovery pumps contain flame arresters in the inlet and outlet pipe. In this case the pump simultaneously may qualify as a protective system (in-line deflagration arrester).

A Notified Body – after having carried out a corresponding assessment of the flame arresting capability – may then issue a separate EC-Type Examination Certificate for the pump as a protective system. In case that both aspects (equipment and protective system) have been assessed by the same Notified Body, only one EC-Type Examination Certificate may be issued.

8.2 Exceptional derogations of the Conformity Assessment Procedures

All equipment and protective systems referred to in Article 1 (1) including components and the devices referred to in Article 1 (2) are covered by the provisions of Article 8 (5).

This article gives the competent authority of the relevant Member State the possibility, in exceptional circumstances, to authorise the placing on the market and putting into service products where the Conformity Assessment Procedures have not been applied. This exception is possible:

- following a duly justified and successful request to the competent authority of the relevant Member State; and,

- if the use of the product is in the interests of protection of health and safety, and where, for example, such interests would be hindered by the delay associated with Conformity Assessment Procedures; and,

- is restricted to the territory of the Member State concerned.

This provision may be applied in safety relevant cases, in which the products in question are needed urgently and there is insufficient time to undergo the complete Conformity Assessment Procedures (or to complete these procedures). The intention is to give Member States (in the interest of health and safety) the possibility to allow the placing on the market and putting into service innovative products without delay. Even in such cases the essential requirements of the Directive must be fulfilled.

With regard to the restrictive application conditions it has to be emphasised that the use of this clause has to remain exceptional and must not become a normal procedure. In the interests of transparency and to assist administrative co-operation Member States are encouraged to provide the competent Commission services with details of any use of Article 8(5).

English